Environmental impact on construction management

December 30, 2020The construction industry has a massive impact on the environment. According to the Environmental Protection Agency(EPA), the U.S. construction industry accounts for 160 million tons, or 25 percent, of non-industrial waste generation a year.

The EPA also reported that 600 million tons of construction and demolition (C&D) debris were generated in the United States in 2018, which is more than twice the amount of generated municipal solid waste. Of that,just over 455 million tons of C&D debris were directed to next use and just under 145 million tons were sent to landfills.

These numbers show why it’s so important that students studying construction management are prepared to implement and address strategies to reduce negative environmental impacts. Capitol Tech’s course in Environmental Systems prepares students for practical applications and understanding critical issues in the field of construction management, including sustainability, renewable energy, and more.

Three Ways to Reduce the Environmental Impact of Construction:

As covered in the course, there are a number of ways to reduce the environmental impact of construction. Among those are three methods reported by Grace Ellis for the Construction Productivity Blog.

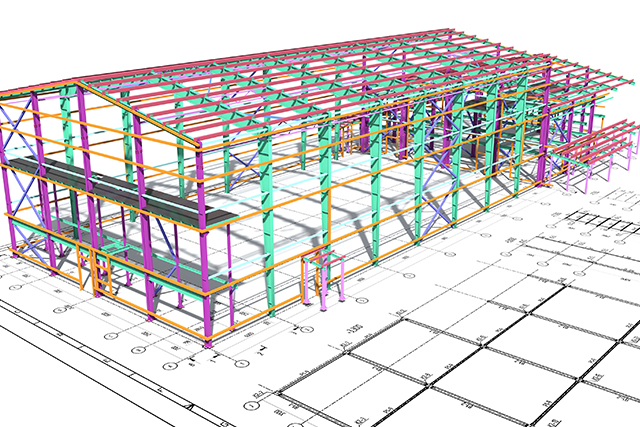

- Building Information Modeling (BIM)

Using Building Information Modeling (BIM) means that construction managers can make more accurate estimates, which leads to reduced waste and fewer errors. Ellis estimates that BIM has the potential to reduce construction waste by up to 45%. BIM also allows for early visualization of a project, allowing for ease of changes and better clarity of the final product, which may reduce waste associated with re-work.

“By implementing productivity savings in the design phase, companies have to deal with fewer last-minute changes and rework” says Ellis. “In turn, this has a positive environmental impact on construction, while also saving construction companies money on lost labor and materials.”

- 3D Printing

In recent years, 3D printing has extended beyond polymer printing of small items to large-scale steel and concrete construction materials. In 2018, a bridge in Amsterdamwas built entirely using 3D printing. 3D printing may reduce the amount of naturally-sourced materials.

“In a project on 3D-printed steel components, Arup [a leading engineering firm] achieved a 40% reduction in materials compared with traditional production methods,” says Ellis.

While this technology is still fairly new to the construction industry, the potential use in the future is limitless.

- Software and Automation

It may seem obvious, but utilizing digital strategies instead of print has a huge impact – in initial stages blueprints and other design documents change with frequency. When not printing those documents and utilizing digital sharing, a large amount of paper can be saved.

Most construction software systems allow for the entire process to be digital – from start to finish, including submittals and sign-offs. Using automated systems have the added benefit of saving time and increasing efficiency.

To learn more about Capitol Tech’s degree programs in Construction Management and Critical Infrastructure, contact admissions@captechu.edu.